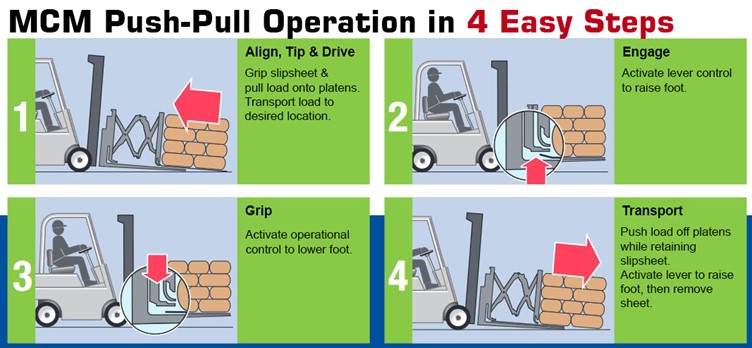

The push-pull allows you to ship, receive, and warehouse unit loads on inexpensive slip sheets rather than pallets. The device slips under the pallet-less load and pushes it off. Replacing the pallet with sheets reduces the cost of packaging. On top of this, it helps to optimize the use of warehousing space. The slip-sheet retainer option allows the sheets of paper, carton or plastic that are placed below the load to be re-used.

Handles Bagged Products

• Agricultural products

• Bottled beverages

• Cased food

• Cement

• Cosmetics

• Electronics

• Seed

Features

• High visibility pantograph, gripper jaw and faceplate

• Full bottom taper/adjustable platens

• Tilting faceplate

• Chamfered platen corners and gripper jaw design protects the slipsheet

• High strength, rigid pantograph for safe load packing

• Protected hydraulics

• Simplified hydraulic circuit

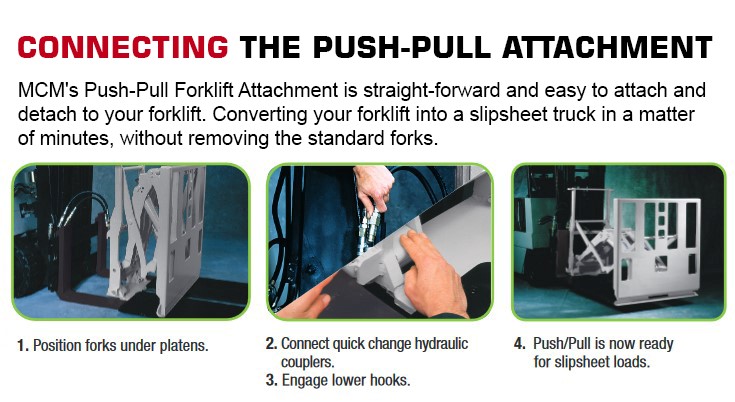

• Fast and easy mounting onto the carriage or on the forks, thanks to an extremely quick and effective fitting system

Smooth and Efficient Load Transfers in Palletless Applications

Why Choose The MCM Push-Pull Forklift Attachment

RELIABILITY: Smooth, powerful performance with precision engineered pantograph. High push and pull force while maintaining protection of internal hydraulics.

PRODUCTIVITY: High visibility faceplate for faster, more accurate load engagement.

REDUCED MAINTENANCE: High strength unitized construction. Cast arms provide more strength than fabricated arms.

DURABILITY: Urethane gripper bar provides tight, secure grip while protecting the slip sheet.

ADJUSTABLE: Platen spacing can be adjusted in seconds (carriage mount models)

REDUCED PRODUCT DAMAGE: High strength, structural steel platens with bevelled tips to protect the slip sheet and load from damage.