Series Contents:

- Forklift Terminology Part 1: Introduction To Basic Forklift Features

- Forklift Terminology Part 2: Mast Details & Dimensions

- Forklift Terminology Part 3: Stability & Manoeuvrability

- Forklift Terminology Part 4: Types of Forklifts & Tires

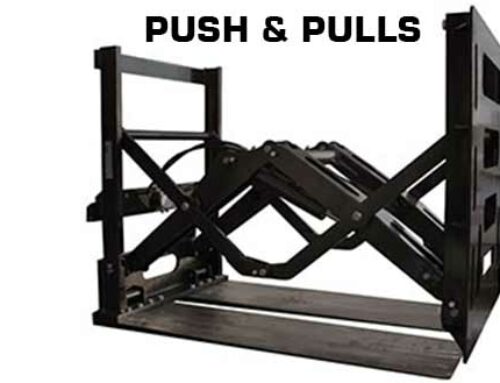

Forklifts Types

A forklift is also known as a ‘lift truck’ because it’s a truck that can lift loads using a its set of forks. A forklift can be used in a variety of places like warehouses, factories, farms, shipping yards and a number of other areas. There are numerous types of forklifts which are called by various names; here we will use the basic names of the forklifts when describing their capabilities:

- Pallet Trucks & Walkie Stackers (Class II): These are typically used for moving pallets and crates of small loads at ground height.

- Electric Warehouse Equipment (Class II & III): Stand-on or ride-on that are used in small spaces. These are quite maneuverable and can lift small to medium loads.

- Electric Counter Balance Forklift (Class I): These are used to lift medium to large loads with a battery powered engine, making it less pollutant (more suitable for indoors) with lower operating costs.

- IC (Internal Combustion) Engine Trucks (Class IV & V): The most commonly used forklift normally outdoors. This type of forklift is typically cheaper to purchase and lifts heavier loads, and works in all types of weather running off liquefied petroleum gas (LPG), liquid propane, diesel and compressed natural gases (CNG).

- Big Trucks: can lift extremely large loads up to 48 tons to very high heights (e.g. shipping containers).

Forklift Tires

Forklift tires are important as they will help with the maneuverability and functionality of your forklift. Improper use and poor maintenance of tires can lead to increased costs. The tires you choose will be dependent on the location your forklift will be working in. There are typically three different types of tires which include:

- Pneumatic: Used in unpaved yards and on rough terrain surfaces.

- Pneumatic Profile Puncture Proof (Semi-Solids): Used on sealed surfaces and areas where punctures may be an issue.

- Cushion: Used on more compact model forklifts in warehouse applications.

- Non-Markers: Made to eliminate black marks on the floor.

Many factors both external and internal can affect your forklifts tire life. Problems can arise from miss treated tires such as punctures or bursts which can result in damaged forklifts, loads or even cause injuries to employees.

If you have any questions or feedback please feel free to leave a comment below. Thank you all for reading and good luck for all your future forklift decisions.

MCM TEAM

Leave A Comment