The comparison between hydraulic road roller and mechanical road roller on compaction performance, safety, and costs will give you a clear picture of the applications of road rollers in today’s marketplace.

Road rollers are mainly used for compacting materials such as gravel, sandy soil, dirt, concrete or asphalt and more in the construction of roads or foundations. When we look at the transmission system, it is mainly available in two types: the hydraulic drive roller and the mechanical drive roller.

Compaction Efficiency and Performance

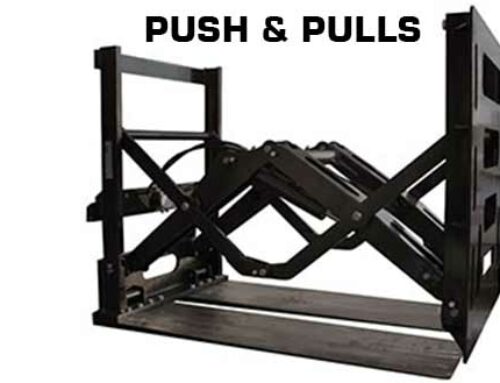

The hydraulic single drum roller is easier to operate compared with the mechanical one; as the operator can automatically change the traveling speed and direction. While the mechanical roller has to be operated manually with complex movements of clutch, gears, and brake. Much time and operator training can be saved by choosing a hydraulic roller. The working efficiency can also be increased.

The compaction performance of hydraulic single drum roller is better than that of the mechanical roller. It takes no more than three second for the hydraulic roller to start its vibration. As for mechanical rollers; a longer time is typically taken to shift from traveling mode to vibration mode.

In road construction, the excitation force required to compact the sandy soil is different from that of compacting gravel. The hydraulic road roller is more flexible and intelligent in the control of the vibratory amplitude and vibration frequency; yet the mechanical road rollers only have two fixed gears and vibration frequency.

Safe and Comfortable Operation

The traveling system and braking system of hydraulic road rollers are all controlled by the same power system, while that of the mechanical roller is separate. When the mechanical roller stops, brake distance is relatively long, handbrake and metal braking parts are also more likely to wear out over time. Particularly, if there are many people and machines on the construction site, the hydraulic single drum roller can stop immediately simply by pressing one button in case of emergency, but it may not be possible with mechanical rollers.

In addition, the hydraulic roller greatly improves the operator’s driving experience; releasing their fatigue, and increasing working efficiency and safety.

Cost Effective

Mechanical single drum rollers are lower in price, but the hydraulic road roller may provide longer service life, and lower maintenance or repair costs.

Nowadays, hydraulic road rollers are predominantly used in the large construction projects including expressway, railways, airport field, big dams or stadiums because only the hydraulic rollers can meet the project’s high requirement of compaction performance. Mechanical road rollers are more suitable for private or smaller construction projects.

With the improvement of design and manufacturing strength, MCM launches its new generation KP80 Walk-Behind Roller and R800 Sit-On Roller.

Leave A Comment