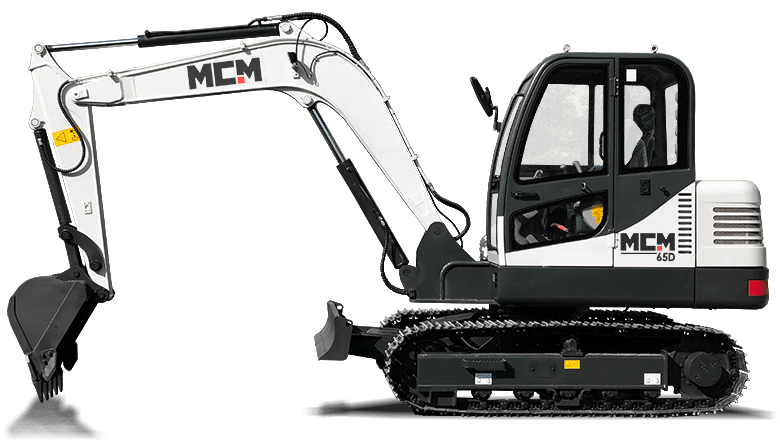

You have selected the

65DS Excavator

Contact Us Today For Your Quote

THE POWER IS IN YOUR HANDS

Tackle challenging job sites with ease in the 65DS Compact Excavator from MCM. You can rely on a solid investment in the durable 65DS, generating profit and growth for your business. Built with high quality components, the 65DS is durably designed to work harder and longer, delivering peak performance and high fuel efficiency.

Do more in less time with outstanding combined digging performance and speed. The 65DS delivers excellent traction, swing force and lifting capacity. For a solid combination of power and productivity, and an improved cooling system ensuring optimized performance for any climate. You can dig, swing, load and lift with increased controllability, for enhanced productivity and reduced fatigue. The 65DS does exactly what the operator intends, thanks to responsive controls and an optimized hydraulic system to achieve precise grading results for a high quality finish.

SPECIFICATIONS

| MODEL | YANMAR 4TNV94L |

|---|---|

| DISPLACEMENT | 3.053 Litres |

| TYPE | Turbocharged |

| CYLINDERS | 4-Cylinder Diesel Engine |

| PEAK POWER | 43kW (57.7hp) @ 2500rpm |

| FUEL TANK CAPACITY | 125 Litres |

| SWING SPEED | 0-11 rpm |

|---|---|

| TRAVELING SPEED | 2.5/4.2 km/h |

| GRADE ABILITY | 35 degrees |

| GROUND PRESSURE | 34 KPa |

| DRAWBAR PULLING FORCE | 30.8 kN |

| BUCKET DIGGING FORCE | 48 kN |

| ARM DIGGING FORCE | 35 kN |

| CIRCUIT TYPE | Axial Piston, Gear Pump |

|---|---|

| PUMP CAPACITY | 2 x 59.2 + 42.2 L/min |

| SYSTEM PRESSURE | 24.5 MPa |

| TANK CAPACITY | 78 Litres |

| TRAVELING MOTOR | Japan KYB |

| SWING MOTOR | Japan KYB |

| OVERALL LENGTH | 5940mm |

|---|---|

| OVERALL WIDTH | 1880mm |

| OVERALL HEIGHT | 2600mm |

| GROUND CLEARANCE | 353-700mm |

| TRACK LENGTH | 2045mm |

| TRACK WIDTH | 400mm |

| SWING CENTER TO TAIL | 1689mm |

| BONNET HEIGHT | 1696mm |

| OPERATION WEIGHT | 6500 KG |

|---|---|

| STANDARD BUCKET CAPACITY | 0.21 m3 |

| MAX. DIGGING DEPTH | 3650mm |

| MAX. VERTICAL DIGGING DEPTH | 3808mm |

| MAX. DUMPING HEIGHT | 3854mm |

| MAX. WORKING HEIGHT | 5499mm |

| MAX. DIGGING DISTANCE | 6124mm |

| TAIL SWING RADIUS | 1689mm |

FEATURES

The 65DS model MCM Excavator is equipped with intuitive operator controls that do not take long to become proficient in. Featuring two multi-function joysticks delivering a number of hydraulic operated functionalities that push jobsite performance. Equip your 65DS with grapples, buckets, augers, hydraulic breakers and thumbs to maximize your excavator’s capabilities.

With four simultaneous operations the bucket, boom, arm and swing can be operated simultaneously and smoothly.

The 65DS front window opens with easy, simply flip the latches on both sides of the window and slide it up. A gas-assist mechanism makes this action almost

effortless.

When operating one-way hydraulic attachments, like hydraulic breakers, rotary grapples, etc, the standard third-line auxiliary return system allows the hydraulic oil to flow directly back to the hydraulic tank without running through the control valves. This means less risk of oil contamination, reduced back pressure, and greater overall oil flow performance.

Maneuver faster with the MCM 65DS’ who-speed travel function. The quicker you can move on the jobsite, the faster you can complete the task at hand. Select low range for pushing and dozing, and high range for increased jobsite mobility.

The 65DS model features an easy-to-use track tensioning system. Simply remove the cover plate, and open the tensioning port by using a socket wrench. To tighten, pump greasing into the tensioner and to loosen, simply loosen the bolt using a socket wrench and the pressurized grease will escape thereby loosening your tracks.

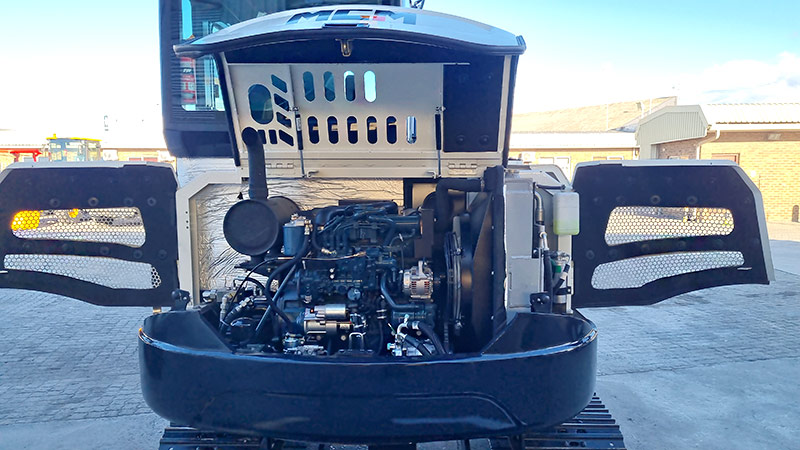

The 65DS model features a rear engine compartment that is truly easy to access. Both left and right side compartment doors swivel open to increase the engine accessibility by a great deal. This allows for easily carrying out routine preventative maintenance as well as getting services done within no time.

The 65DS MCM Excavator can be equipped with a hydraulic quick hitch which makes it much easier to exchange between attachments, in turn increasing efficiency on the jobsite. A mechanical quick hitch is also optional which works by tightening or loosening a bolt by hand, that opens and closes the hitch mechanically.

IMAGES

VIDEOS

OPTIONAL ATTACHMENTS

– Buckets –

– Rippers –

– Thumbs –

– Grapples –

– Augers –

– Tracks –

– Shears –

– Hydraulic Breakers –