Do Not Leave Your Cut Trees Lying For Too Long

Your climate, terrain and the species of tree you intend to process, will play a large role in how long you can leave your freshly cut trees on the ground before bugs and moisture begins to settle in. Both these are unwanted, leading to added wastage and stains in the lumber. You’ll need to determine the average maximum time you have before your initially cut trees need to be moved either for storage or for processing.

Your Sawmill Must Be Level

Such a simple thing as your sawmill not being level will greatly affect the quality of your cut.

Make sure you’re Portable Sawmill is as level as possible before you begin processing your trees. A quality cut is what you’re after.

Clean Your Trees Before Processing

You’ve either got to keep your trees clean, or if they get dirty once initially cut you should consider cleaning them before lining them up on your Portable Sawmill. By doing this, you’re going to avoid unnecessary expenses such as sharpening or replacing your blades more frequently. By cleaning the lumber before starting to mill it, the dirt and soil material will not contribute to dulling your sawmill’s blade.

Cut Lumber Needs To Be Stacked & Stickered

Decide on the size stickers/spacers you’re going to use to separate your lumber and provide maximum air flow for drying. Lumber can either be kiln dried or naturally air dried. By stacking your lumber on stickers, it allows ample airflow in between the stack thereby accelerating the drying process. Remember, lumber enjoys fresh air and hates bugs and moisture. If a kiln drying process is used, depending upon wood species, the kiln is heated to temperatures between 40 to 80 degrees Celsius for conventional-temperature kilns and 110 to 140 degrees Celsius for high-temperature kilns.

Our advise is to place your stickers in line with one another from bottom to top. Keep your stickers the exact same size respective to one another. Prevent warping. How many stickers do you need? LOTS! And lots more!

Apply Pressure To Your Lumber

It will be good to apply a downward force onto the top of your stack. This will prevent the lumber from warping during the drying process.

Lumber Doesn’t Enjoy Bugs & Moisture

Most insect borers are attracted to weakened, damaged, dying or dead plants. These are referred to as “secondary invaders” because they attack only after a plant has been weakened by another stress. Secondary invaders are a symptom of other problems with the health of the tree or shrub, but may contribute to its decline. Secondary invaders include species like termites, carpenter bees and carpenter ants.

High Quality Lumber when being dried, also doesn’t enjoy moisture. See below and get yourself a moisture detector.

How Will You Deal With The Waste?

Running a Sawmill results in large quantities of waste that need to be dealt with. It is important this waste; like wood chips, sawdust, cut pieces, etc, be dealt with appropriately to manage waste and sustainability.

Sharpen Your Blades

Keeping your blades sharp ensures a higher quality cut. The sharper the blade, the lower the heat generated during cutting. What other advantages are there to keeping your blades sharp?

Swaging makes the tooth tip wider than the blade thickness and helps prevent heating of the blade during cutting.

After swaging, band saw blades are then sharpened by grinding, often with an abrasive aluminum oxide wheel and sharpening machine. The sharpening tool must be run at the correct speed to prevent blade damage. The proper wheel thickness also ensures adequate sharpening. In general, the sharpening wheel should be around half the length of the tooth pitch in thickness.

You can also sharpen a blade manually by applying a Dremel tool to the tip and gullet. Manually sharpening a wide band saw blade can be a time-consuming process and requires a steady hand. Industrial sawmills, which need regular sharpening to boost efficiency and reduce downtime, greatly benefit from the use of grinding machines.

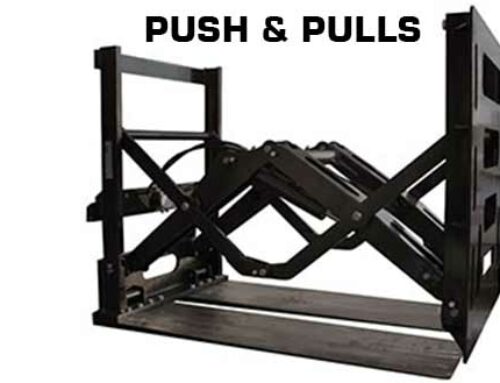

Green Lumber Is Heavy

What equipment do you have ready for handling the trees once initially cut?

How will they be taken to your Portable Sawmill?

What will you use to handle the green lumber once processed? Freshly processed lumber is heavy due to moisture content.

MCM has a number of equipment options available that will make tree and lumber handling an effortless and efficient task.

Quality Pays

The profitability of lumber manufacturing depends on the mill’s ability to maximize the wood’s quality throughout the entire lumber manufacturing process. If the wood in a mill’s production line is too wet or too dry, the finished product may receive a lower grade and will have a lower value than a piece that has been properly kiln dried.

The lumber manufacturing process generally follows these steps:

- Head/Main Rig: The primary saw cuts the tree into sawn pieces or boards.

- Edging: Removes irregular edges and defects from sawn pieces or boards.

- Trimming: The trimmer squares off the ends of lumber into uniform pieces.

- Rough Lumber Sorting: Pieces are separated based on dimension and final product production, whether the finished piece will be unseasoned (known as “green”) or dry.

- Stickering & Stacking: Lumber destined for natural air drying or kiln drying production, is stacked with spacers (known as stickers) that allow air to circulate within the stack (green product skips this stage and the next).

- Drying: Kiln drying wood speeds up the natural evaporation of the wood’s MC in a controlled environment.

- Planing: Smoothes the wood’s surfaces and ensures that each piece has a uiform width and thickness.

- Grading: Assigns a “grade” to each piece of lumber that indicates its quality level, based on a variety of characteristics, including its Moisture Content (MC).

Get Yourself A Moisture Meter

When it comes to operating a portable sawmill and then drying your own wood, the moisture content (MC) of your lumber can greatly impact the overall quality. Whether you are air-drying, or using a dry kiln, you need reliable and accurate sawmill moisture measurement equipment to make sure your lumber is at the correct MC for your projects and any of your lumber customers.

Wagner Meters offers an advanced line of hand-held moisture meters that are ideal for harsh, industrial environments.

Get In Touch

Want to find out more about MCM’s 420 Model Portable Sawmill? Follow this link; Click Here.

Leave A Comment