It’s important that your excavator is ready to work when the job is at hand. There are bad habits and patterns that can compromise the performance and useful life of your excavator. We’d like to assist by pointing out 7 bad practices.

1. Digging Over The Drive Motors

There are exceptions to every rule, however it is advised to avoid digging over your excavator’s drive motors. The drive motors are expensive to replace and digging over them will cause unnecessary stress and wear on these vital component, accelerating the time a replacement is required.

Keeping the drive-end away from the work being done, ensures that the force and pressure is applied to the tracks and idlers which is good. Working this way additionally protects the drive motors from being damaged by falling debris.

2. Forgetting About Your Counterweight

Always be aware of how far your counterweight hangs over your tracks and the different obstacles on the jobsite around you. Always set yourself up with appropriate clearance!

When working in tight spaces or urban environments, a zero-swing is a great option to avoid having to navigate tail swing. Check out MCM’s Zero Tail Swing Models here: CLICK HERE

3. Using The Wrong Attachment For The Job

Using a bucket that is too small or too large for the specific job may decrease efficiency as well as lead to other problems. The wrong sized bucket can be more difficult to control, cause your hydraulic system to run hotter, and reduce the fuel efficiency.

4. Running Full Throttle

The excavator engine should only run at full throttle when required, because full throttle does not equate to maximum power. The only thing that is increased disproportionately are the fuel costs. Speak to your dealer if required regarding the optimum recommended engine rpm’s for the various tasks at hand.

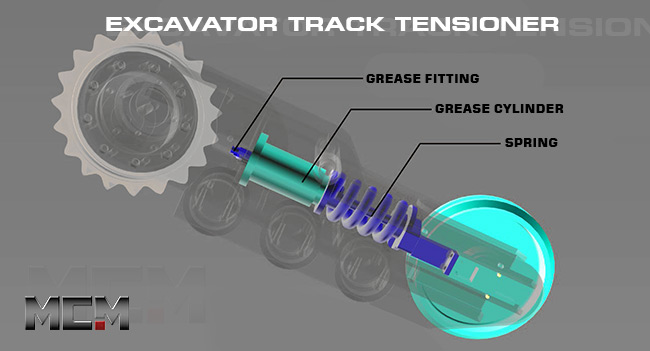

5. Adjusting the Tension on Your Excavator Tracks

Tracks are an important part of the undercarriage and often need the most frequent adjustments done, ex. tracks elongate over time and thus they need to be tightened. How often the tracks need to be tightened depends on the applications, the terrain, and of course the operator. Tensioning the tracks could be required as frequently as once each day, or once a week. However, MCM recommends the track tension be checked daily before each use, as part of the Pre-Start Maintenance carried out.

Tracks that don’t have sufficient tension will wear out faster. Alternatively, tracks that have too much tension will also wear out faster. Tracks should sag a little at the top between the two rollers.

How you measure sag will depend on whether your excavator is equipped with a single-top-roller undercarriage or a two-top-roller undercarriage.

6. Not Cleaning The Undercarriage

Undercarriages are one of the more costly parts of an excavator to repair and replace. One easy way to contribute to the long life of your undercarriage is to clean it. When it isn’t cleaned regularly, debris can get packed in tightly and harden. Debris can even push aside seals and introduce abrasive contaminants into the system. Cleaning the undercarriage should be a daily practice on demanding job sites as, this also enables inspections to be done more effectively.

Additionally, excessive debris built up will result in added weight, which results in heavier fuel consumption.

7. Forgetting About The Final Drive Gear Oil

Never forget your final drive! It is what allows your mini excavator to move. MCM recommends checking the final drive gear oil level should be done every 50-100 hours. If operation continues while oil level is too low, the drive can be damaged.

Also remember that gear oil, just like any other lubricant, will began to degrade with time thanks to the exposed to heat. So it is crucial to ensure that your final drive gear oil is replaced as regularly as advised and/or required by the manufacturer.

Final Words

If you want your mini-excavator to have a long life with minimal downtime and maximum efficiency, avoiding these seven things will certainly help. Remember, maintenance is key. There is a difference between scheduled services and regular or preventative maintenance.

Stay tuned for more helpful tips on MCM’s Resources Blog Page. We hope to assist where we can. Feel free to leave a comment if you can add value to our post and thanks for joining us. Keep digging!

Leave A Comment