By performing regular preventative maintenance checks on your rubber tracks, it can significantly help increase their lifecycle. Daily maintenance tasks include visual inspections of the tracks and undercarriage while keeping an eye out for signs of cracks, tears, cuts, or excessive wear.

The tracks, idlers and rollers should rotate smoothly when under power. The sprockets should not have missing or overly worn/sharp teeth. It is also vital to check fluid levels, their conditions, and hydraulic lines.

Daily Preventative Maintenance Checklist for Rubber Track Maintenance

- Visually inspect hydraulic lines for any leaks or damage.

- Clean out undercarriage and tracks with a pressure washer.

- Inspect the undercarriage and tracks for damage and excessive wear.

- Check track tension.

- Rollers and idlers should rotate smoothly and freely under power.

- Tracks should move smoothly without slipping and not have any cuts, tears, or cracks.

- Sprockets should have all of their teeth, and the teeth should not be overly worn down or sharp.

Achieve The Best Track Life

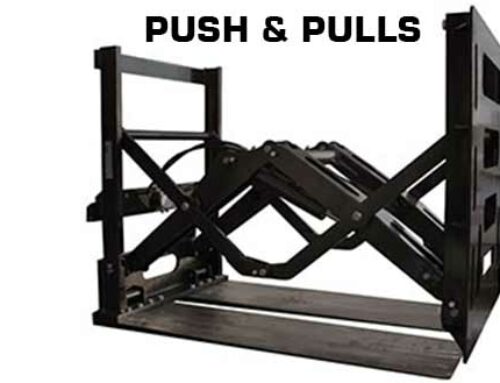

A loose track can result in ratcheting — lugs skipping over sprocket rollers — which accelerates wear or damage to the lugs. A loose track also increases the risk of derailment. Alternatively, a track that’s too tight can accelerate wear on bearings, wheels and sprockets. Next, look at the drive lugs. Like the track, lugs encounter wear over time, especially when working in abrasive materials. Side slopes can also be hard on lugs, resulting in one side of the lugs wearing more than the other. Check that the lugs still fit well with the sprocket rollers. A track isn’t usable if lugs are worn down so far that they continually skip over rollers when the track is properly tensioned. This usually happens when about 50% of the lug is gone.

Six Factors That Influence Rubber Track Wear

- Track tension,

- Weight of the load (machine weight plus load weight),

- Driving speed,

- Driving behavior (working on slopes, rocks, making sharp turns, etc),

- Ground surface and temperature,

- Operator awareness.

Good Operating Techniques

Operator should avoid sharp turns, spinning, constant operation on slopes, and contact with the track sides on curbs or obstacles. Operator should avoid exposing the rubber tracks to broken stone, sharp materials, high heat, fuel, oil and salt. If operation on these and similar materials is required, ensure to clean the undercarriage with clean water daily.

Long Term Storage

For long-term storage, move the machine under its own power for five minutes every other week. This helps keep the tracks flexible and prevents fluids from coagulating.

Prevention Beats Repair

By taking the time to perform the above daily preventative maintenance tasks, you’ll help ensure the longevity of your rubber tracks while limiting costly downtime. If you have any questions about the maintenance of your rubber tracks get in touch with us.

Leave A Comment