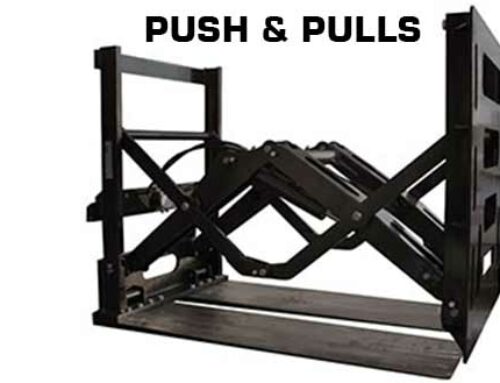

No ground is too soft nor too hard for hydraulic powered trenching attachments. Trenching applications include pipe laying for irrigation, underground power & communications lines, raft foundations, sewage lines, road repairs and general construction. Here at MCM, we offer a number of trenching options to best suit your needs but before we get there, lets explore the different trenching details.

Whether you are thinking of purchasing a trencher machine or are deciding to get a rental unit, there are a few things to consider:

1. How deep do you need to go?

Topsoil excavation depth varies from site to site, but generally entails a depth between 150mm and 300mm. Earth excavation involves going deeper than topsoil levels. But in this case, we will focus on depths of 1.2m or less.2. What is the underground condition?

2. What is the ground composition where you will be trenching?

Are you trenching in soft, agricultural ground, clay, sand, gravel or compact rocky areas? Answering this questions will help you decide which trenching option is best suitable for your terrain.

3. How wide does the trench need to be?

Generally, trenching widths range from 100mm to 250mm. And depending on what your needs are, you need to make sure you get the right equipment.

4. How much space do you have?

Is the space you have limited or is it in an open field? Depending on the available space, you could look at different equipment. The MS30 Compact Track Loader for example, can operate in a very limited space with a machine width of only 1,05m and length of only 2.6m. (See the MS30 in action a video below on a trenching rental job). Able to turn on the spot with no turning radius due to it being a tracked machine. For larger applications, we look at the 3 available models in the CL-Range. These Compact Loaders have articulating central joints to greatly increase maneuverability and decrease the turning radius.

Different Chain Setups

Here at MCM, we offer 3 trencher chain options:

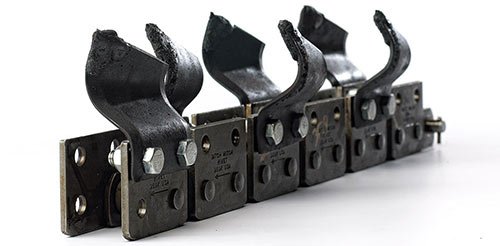

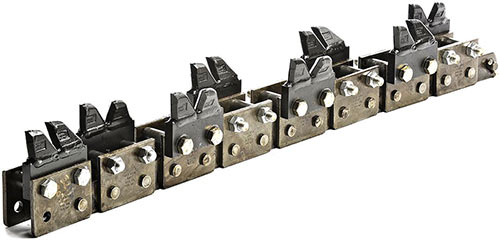

- Earth Chain – Best suited for soft ground and earth. This chain is equipped with curved or cupped trencher teeth (The below video shows trenching in soft agricultural soil with the Earth Chain Setup).

2. Shark Chain – Best suited for compacted soils, light frozen ground, hard clay, shale or rocky soils.

3. Combination Chain – Allows for use in a range of conditions from hard soil, roots and rocky ground. This chain is equipped with both cup teeth and shark teeth. The aggressive shark teeth will slice, break and relieve the tough soils, allowing the cup teeth to follow and clean the trench.

We know contractors are good at getting the most out of the equipment they have, but taking the time to really examine trenching needs and terrains prior to purchase/rental can significantly help the company in terms of owning/operating costs, maintenance, fuel use, transportation, etc.

MCM provides a number of trenching options that you should consider, from compact loaders and track loaders to excavators.

Leave A Comment