Trenching is probably the major task mini excavators are used for. Landscaping for drainage, placing pipelines, raft foundations, sewer lines, fiber cables, fencing, etc.

According to Johannes van Niekerk, MD for MCM, “The purpose is often to get in there, get the job done as efficiently and cost effectively as possible, and then to get out so you can do the next job. So, speed is key yes, but efficiency determines that speed. The important question is; what determines efficiency.”

Trenching is an important part of construction, agriculture, landscaping and other industries. We hope to provide some deeper insight into trenching that may assist you.

1. Excavator vs. Trencher

MCM’s Mini Excavators can work in the confined areas and greatly improve efficiency on the jobsite. A project that would take one or more people a full day to dig, may take a mini excavator an hour or two. For instance, instead of several workers using a jack hammer to break up an old driveway or sidewalk, a mini excavator can come in with a hydraulic breaker attachment and complete the job in a fraction of the time.

Then, when finished, the operator changes over to the bucket, and that old material is loaded into a truck. Using a machine to complete these challenging tasks and move the heavy material will allow the construction workers and laborers to have more time to work on the projects where a mini excavator can’t help. The excavator’s grader blade can be used for grading, backfilling and leveling.

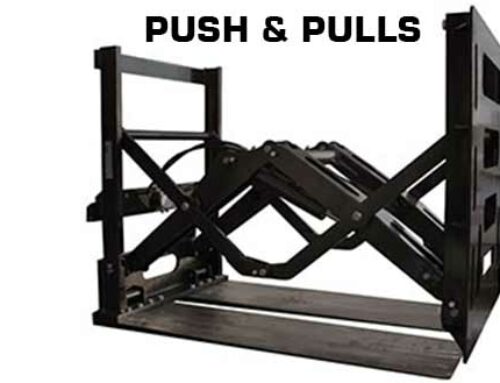

MCM’s Compact Loaders and Track Loaders offer another perspective. These machines are very different to excavators, yet also provide high levels of efficiency when it comes to trenching. MCM offers a range of trencher attachments which easily mount onto the CL-Range, ML-Range or MS-Range machines.

“The trencher-equipped machine cuts precisely, and trenches fast,” says Van Niekerk. “These trenchers only excavate the material that requires removal. It produces an even trench all the way up to the top. Depths can be manually adjusted as per each job’s requirement and the spoil can be used for backfilling.”

Generally a trencher can deposit the backfill on the side of the trench much faster than an excavator. The backfill deposit is also fine material compared to lumps of material excavated by an excavator. Once the trench has been completed, the same machine can quickly exchange the trencher attachment for a dozer blade or even a bucket to push the backfill material back into the trench.

Trenchers are one of the most common attachments for compact loaders, skid steers and track loaders.

2. Plan Your Depth, Length, and Positioning

Operators should follow the construction plans closely, dig in a straight line and ensure the trench is wide enough for utilities to be installed. Additionally, they should make sure the trench walls are sloped properly, preventing them from caving in. This will help keep workers safe who may need to enter the trench to weld pipe or join other utilities, etc.

When backfilling, operators should make sure large rocks or other materials do not damage utilities. Soft dirt needs to be carefully added to the trench, then the dirt should be carefully compacted once finished.

Below are a few tips for Trenching With An Excavator;

- Ensure your equipment is well-maintained, you’ve done the pre-start checks and your excavator is ready for the job.

- Use a surveyor’s level or laser level to mark the trench placement. Or if those aren’t available, a can of spray paint or spreading chalk can work.

- Use your track marks to help keep you in line.

- Point your undercarriage towards where you’re targeting while keeping your upper house square while digging.

- Positioning your tracks so that the trench is aligned with your left or right track. This means digging on the inside of the left or right track respectively is done, which some operators prefer.

- Dig in layers instead of digging to the required depth straight away. Remove the top layer of soil and make your way down to the required depth.

- Keep track of the center line when digging a v-ditch by making sure the center line of the ditch is deeper than the slopes.

Below are a few tips for Trenching With A Trencher-Equipped Machine;

- Remain steady, and calm. Trenching efficiency rests largely in the hands of the operator.

- Be alert and constantly aware of the soil condition you’re trenching in. Hitting rocks or a bed of rock can damage the trencher teeth, or slow down operation. Know your trencher chain setup to ensure you know in which soil conditions your trencher can safely trench in. We have written about What Trencher Chain Setups to use and why, which you can view here: Click Here To Read.

- Despite wear and tear, like any machine, the life of a trencher can be extended with proper use and preventive maintenance.

- Ensure the ground you’re trenching in is level. You can’t dig a level trench unless the machine is absolutely level.

3. Reflect and Improve

At the end of your trenching project, section or simply at the end of the work day, ask yourself or the operator critical questions such as;

- What did I/you learn?

- Is there an aspect of my/your trenching application which can be improvement upon?

- Is the equipment appropriate for the job?

We also recommend inspecting your equipment before the end of each day/project. This will ensure your equipment is ready before each day and in the case of discovering an item requiring attention or maintenance, reduces and/or prevents down-time.

While some of these tips may seem obvious, it’s often the small, seemingly simple practices that can get overlooked and missed. Excavating is a skill developed over time. With practice, you’ll gradually develop an intuition of how to do it well and even then.

We’d love to hear your thoughts about trenching! What tips do you have for others? What has worked best for you?

Leave A Comment